The hydrogen vent is a mid game source of power generation (and late game rocket fuel). These vents are very hot and will kill your base without cooling. To tame a hydrogen vent you will need a fair bit of steel and ceramic material. This design is power positive and quite stable.

Setup

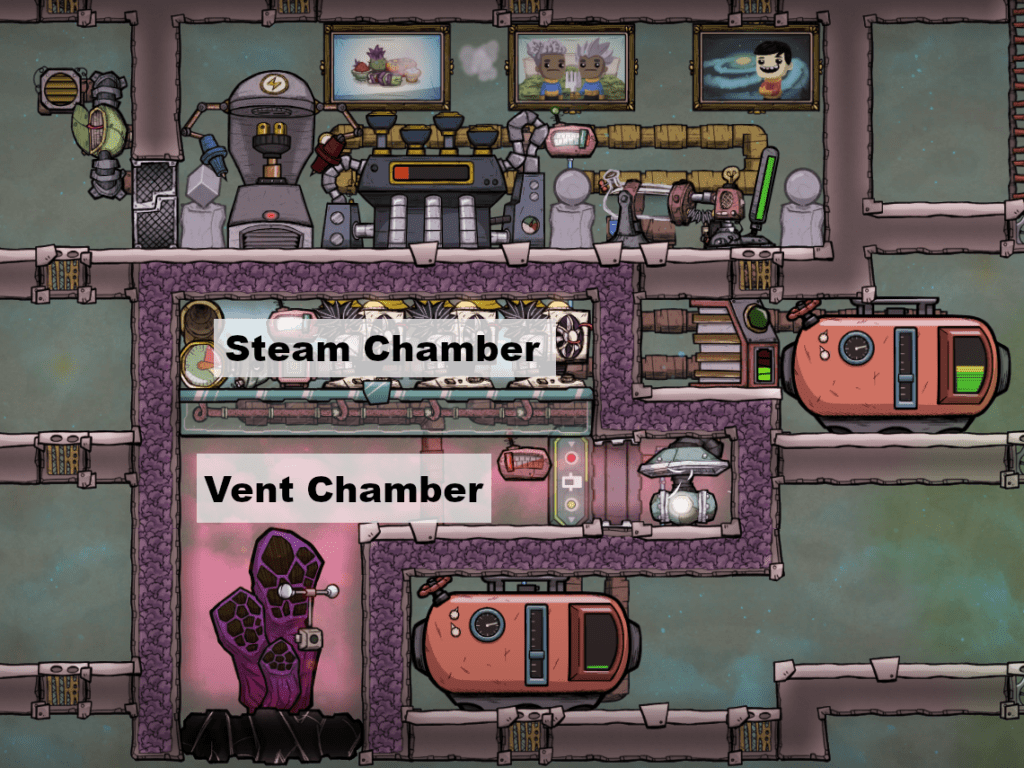

Make sure you have researched steam turbines, thermal regulators, and basic automation. Hydrogen will come from the vent at around 500°C (932°F), this is hot enough to break steel machines, so we will cool in 2 stages. Wall the hydrogen vent off while the rest of the system is setup.

Stage 1, Initial cooling

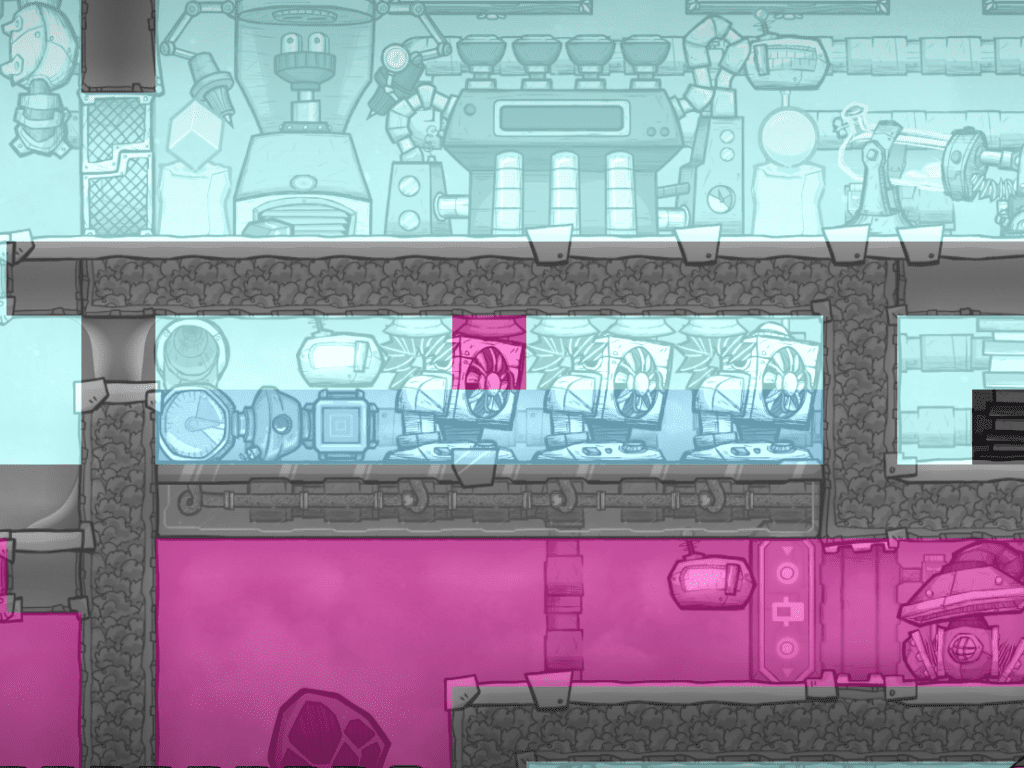

Step one is to cool the gas in vent chamber by heat transfer to the steam chamber. Our steam chamber has a floor made of “High Thermal Conductivity” diamond tiles, this will transfer heat effectively. Any material with “High Thermal Conductivity” will do. This will cool the gas to around 125°C (257°F) before moving it into the cooling loop.

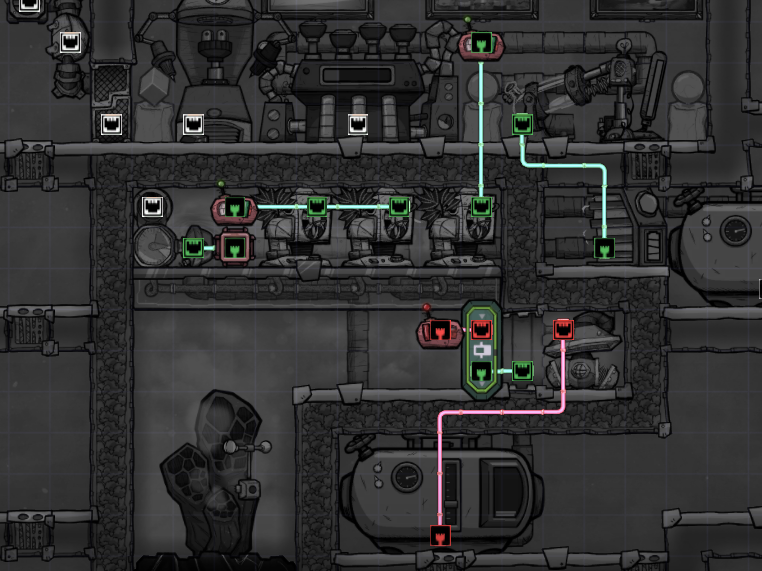

However there is one extra step, we need to prevent fresh hydrogen gas that is too host from reaching our gas pump too soon. Our steel pump can only handle 275°C (527°F) before breaking, this is where a thermo sensor controls a mechanized airlock system. The thermo sensor in the vent chamber sends a green signal if the temperature is below 130°C (266°F), which opens the lock to allow the pump to move the gas into stage 2 cooling. A buffer gas set to 30 seconds allows a decent amount of gas to move before closing. See automation layout below.

Stage 2, full cooling

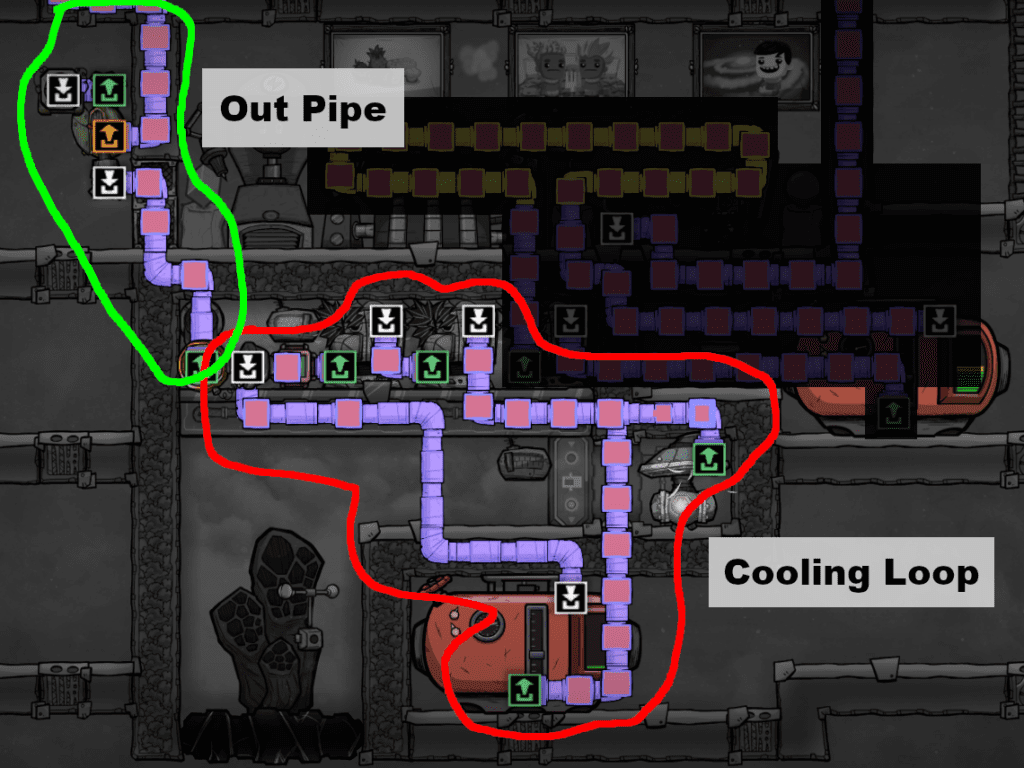

The cooling loop (in red) is the complicated part of the build, but worth the effort as it will cool gas to any temperature we set.

This loop takes the gas from the pump and sends them to the 2 middle thermo regulators. Next a gas pipe thermo sensor checks the pipe gas temperature and sends a green sign if the gas is below a certain temperature, I set this to 0°C (32°F), but it can be any temperature. On green signal the gas shutoff opens and allows the gas to move to the out pipe for power and storage. If the gas is still too hot, then it moves back down to a gas reservoir.

It’s important that the gas pipe thermo sensor and gas shutoff are right next to each other, so the exact gas unit gets checked.

The gas reservoir has an automation wire connected to the gas pump (see automation layout below). This is important as it will prevent the gas pipes from filling up and locking the system. Set the high threshold of 10 and low thresholds to 0. This will allow gas to enter the cooling loop, reach the correct temperature before exiting out.

As an extra safety feature the 2 middle thermo regulators have a thermo sensor to switch them off if the steam chamber gets over 200°C (392°F). Over heating can be an issue in the setup, so it’s best to limit how hot things get. If the steam turbine is over heating the surrounding area try a lower setting but keep it above 130°C (266°F).

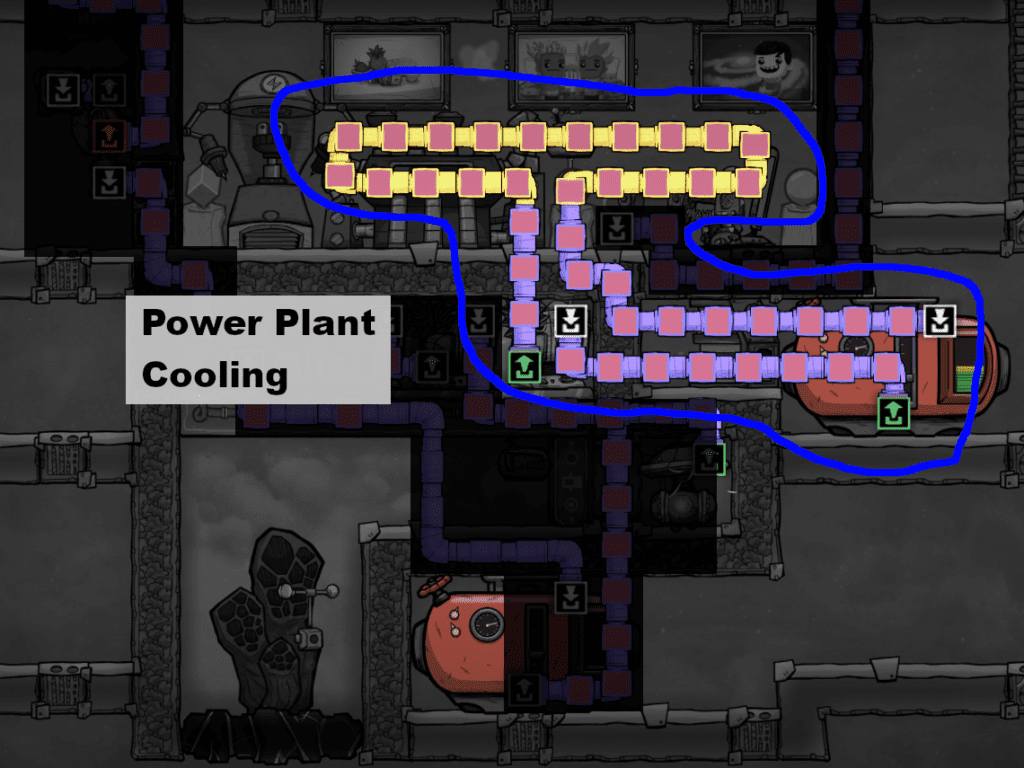

Power plant and Cooling

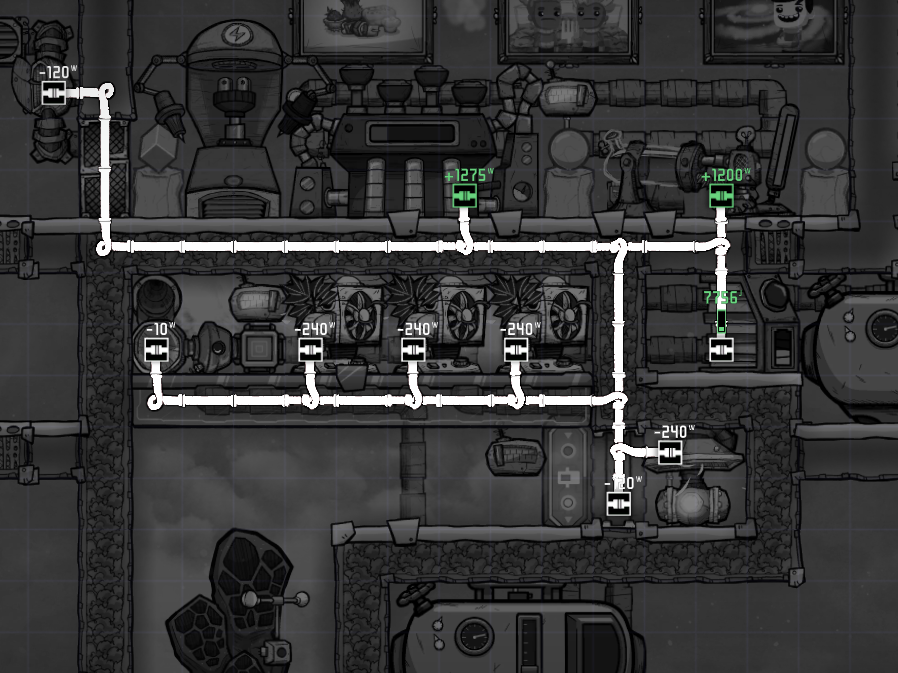

You will have noticed an extra thermo regulator and set of pipes. This is a power plant cooling system, with thermal sensor between the steam turbine and hydrogen generator, it activates if the temperature is over 20°C (28°F). It makes use of the already existing steam chamber, and provides easy cooling to prevent the base from over heating. A gas reservoir keeps the cooling hydrogen circling around.

A power plant hydrogen generator and smart battery provides all the power we need. The steam generator runs without the smart battery as it’s main job is to delete heat.

Tips

Starting the system can be tricky, with the steam chamber you can pump some water in or build some ice temp-shift plates (which will melt). Then it’s a matter of time until it turns to steam. You’ll need the steam to push any oxygen out of the steam chamber before closing it off. If a layer of oxygen gets trapped between the steam and turbine the system will overheat and break.

Always have enough storage, don’t let the system lock up. If the system locks up, the cooling loop will continue to cool the gas until it turns to liquid and breaks the system. If you need to, vent excess hydrogen to space.

Use insulated ceramic tiles to keep the heat trapped. Ceramic tiles will greatly reduce heat leaking into your base.

Use a gas filter to separate any trapped oxygen from hydrogen gas before sending to storage. This will prevent any hydrogen generators from being damaged when they use the gas.